Dynamics Field

Toward the development of next generation car technology

Research Contents

Education and research in the Dynamics field focus on automobile hardware, especially power sources for automobile, car aerodynamics and automobile structure and dynamics, as well as material mechanics and air pollutants.

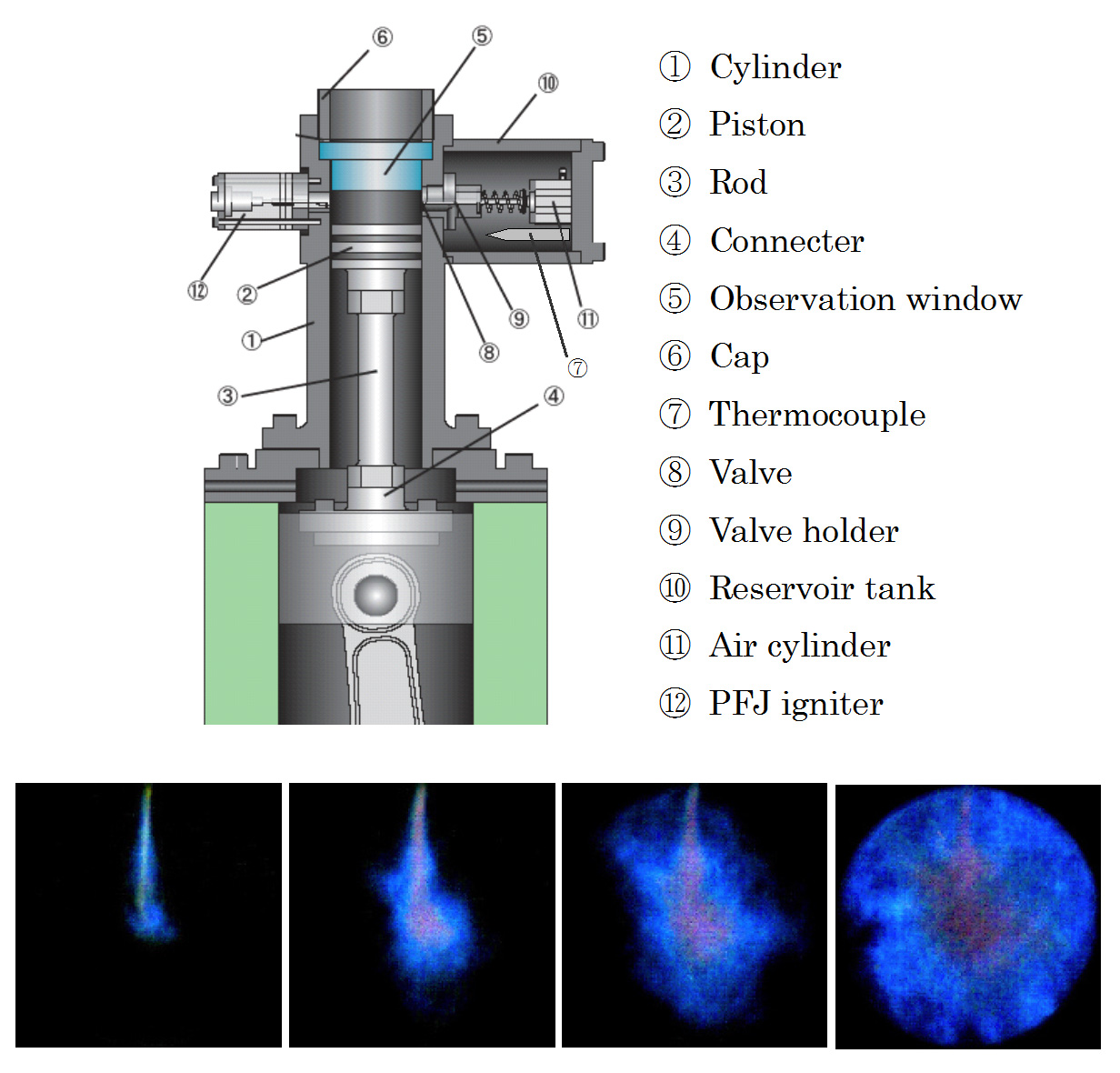

Combustion for the next Generation Engine

For the power sources of the next generation automobiles, our research focuses mainly on the power sources using combustion. These photos show the combustion in an engine that is called HCCI (Homogeneous Charge Compression Ignition). This HCCI is regarded as a solution to energy and air-pollution problems. HCCI engines have not yet been used practically because it is very difficult to control the start timing of combustion. We are studying how to control the combustion by using Pulsed Jet Ignition.

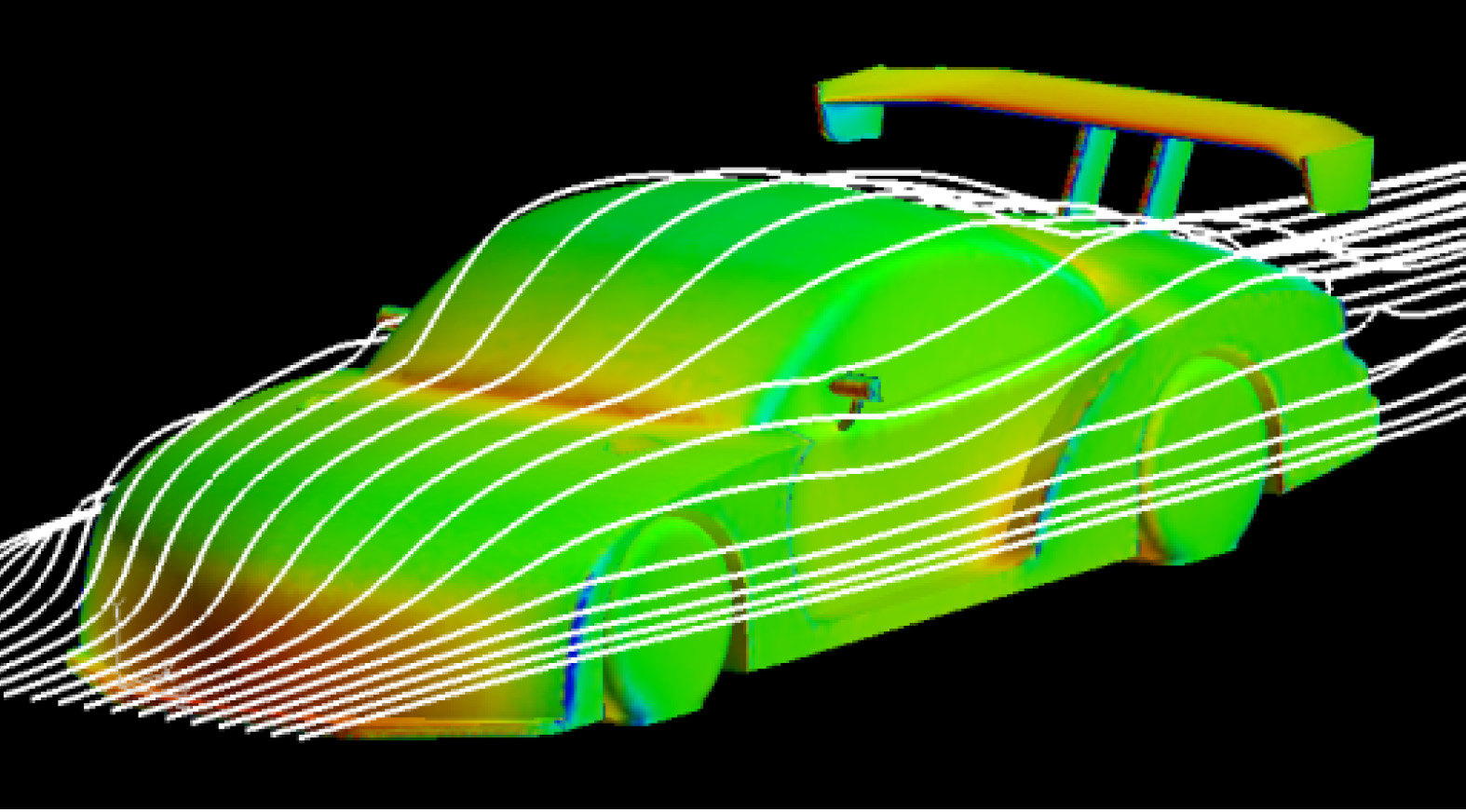

Investigation of Flow Phenomena and Application to Car Technology

Car technology has strong relation to fluid dynamics in many ways. Needless to say, fluid dynamics plays an important role not only in car engineering but also in many mechanical design processes. In this field, we are studying wide range of complex flow phenomena, leading to more advanced car-body design from the viewpoint of car aerodynamics.

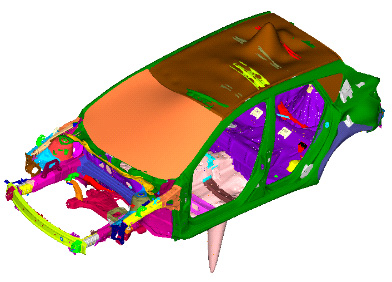

Vibration Control and Precise Assembling in Automobile Structure

Vibration problem of automobile is important because it directly concerned with noise and harshness. Vibration control is indispensable to keeping ride quality of automobile. Another important point in automobile manufacture is high measuring technique to evaluate the assembling accuracy of the automobile structure, because high precision assembling is required in recent automobile manufacturing.

Classification of vibration mode for efficient design of automobile body

As a performance of computer improves, in-depth models of finite element method (FEM) have been treated in vibration analyses of automobile structures. A precise vibration analysis of the automobile structure can be implemented by the FEM, on the other hand, huge number of vibration modes are obtained through the FEM because the huge number of degrees of freedom caused by the in-depth model. It makes a design of countermeasure against harmful vibrations, which give bad ride quality and harshness. In this study, a design technique to classify the vibration mode according to the characteristics of the vibration pattern. This technique is able to designate the significant vibration mode, and facilitate making the countermeasure against the harmful vibration.

Nondestructive technique with instantaneous frequency of an ultrasonic pulse wave to evaluate assembling accuracy of the automobile structure

An automobile structure is composed of various machine elements, which are connected each other using tightening bolts, welding and so on. In recent automobile design, many machine elements require high precision assembling because of a high functionality of the mechanism. However, there is no technique of nondestructive inspection to evaluate the assembling in manufacture process. Exact evaluation of the tightness of the bolt and welding, even with a destructive technique, is well known to be difficult. In this study, a novel nondestructive technique utilizing instantaneous frequency of an ultrasonic pulse wave is proposed in order to make the highly difficult inspection come true. The proposed technique possesses a prospective potential to improve reliability of the automobile construction remarkably.

Teaching Staff

| Faculty Members | Lab Location | Graduate Faculty | Education and Research Area |

|---|---|---|---|

| Prof. Ken-ichi Abe | Ito Campus | Faculty of Engineering | Fluid mechanics, computational fluid dynamics |

| Prof. Takumi Inoue | Ito Campus | Faculty of Engineering | Dynamics of machinary, Mechanical vibration |

| Prof. Osamu Moriue | Ito Campus | Faculty of Engineering | Internal combustion engine,Combustion |